E-scrap

As technology advances at a rapid pace, electronic devices have become an integral part of our daily lives. However, with this rise in technology comes the challenge of managing electronic waste responsibly.

Electronic scrap is a highly complex and heterogeneous group of materials. We have the expertise required to correctly valorise and refine different types of precious metal bearing e-scrap. Umicore works with an assay-based settlement and typically valorises silver, gold, palladium and copper. Elements such as aluminium and iron are not valorised, and we recommend removing these fractions beforehand as much as possible. Batteries are considered a safety hazard in our flow sheet and need to be removed before arrival at our plant.

By recycling end of life electronics, we do not only ensure these materials are not landfilled, but we also decrease the need for virgin metals. We prioritise environmental sustainability and adhere to strict regulations and industry standards. Our recycling processes are designed to minimize the environmental impact of e-scrap, ensuring that valuable resources are recovered and hazardous materials are handled safely.

Which types of material does Umicore take? Below you may find an overview of the typical materials we work with, and the ideal lot sizes.

| Materials | More information | Recommended minimum volume | |

| Printed circuit boards (PCBs) in various qualities | 10 tons |  |

|

| Cell phones and other small IT devices without batteries |

Batteries can be recycled as a separate material by Battery Recycling Solutions | 2 tons |  |

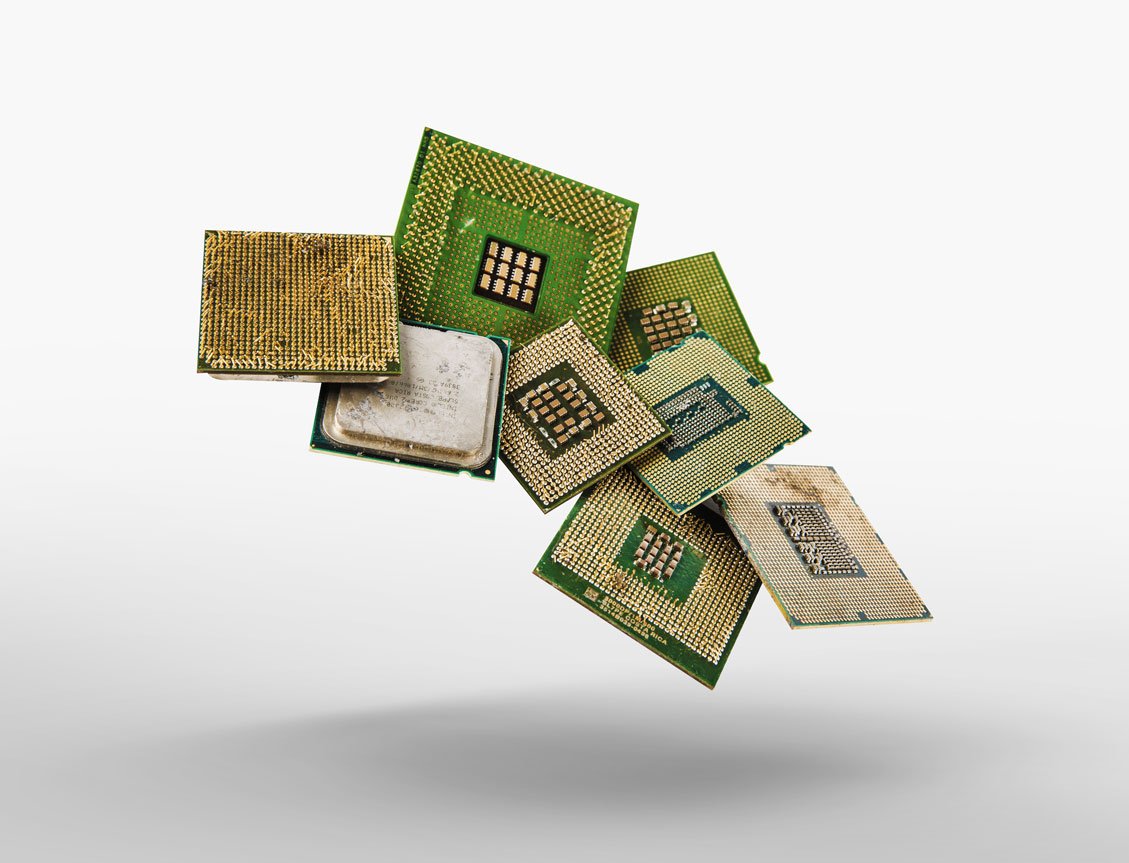

| CPU, IC, connectors | 1 to 5 tons |  |

|

| Laptops without batteries & screen |

10 tons |  |

|

| Shredded fractions with printed circuit boards |

From mechanical pre-processing of e-scrap | 25 to 100 tons |  |

| Other precious metal bearing fractions |

Please contact us to find out more |

||

Umicore reinforces its compliance with the WEEE end-processing standard. Click here for LRQA's certificate of approval.